Denso™ Encourages Customer Confidence Through Free Product Application Training Sessions

At Winn & Coales (Denso) Ltd, it’s extremely important to us that our customers feel confident in applying our corrosion prevention and sealing systems. Ensuring the longevity and cost-effectiveness of every application begins with helping our customers select the most suitable Denso™ products for their individual project requirements, along with offering free product application training that’s available throughout the UK and beyond.

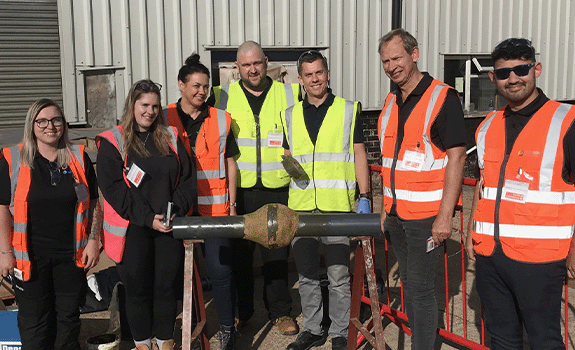

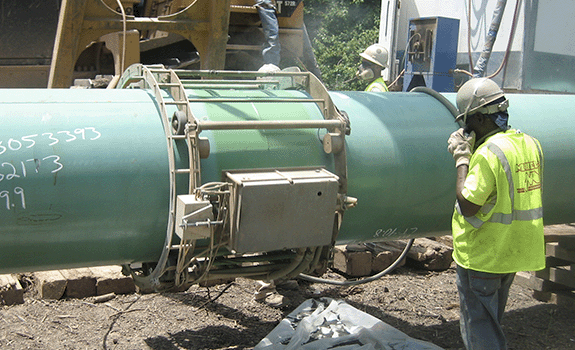

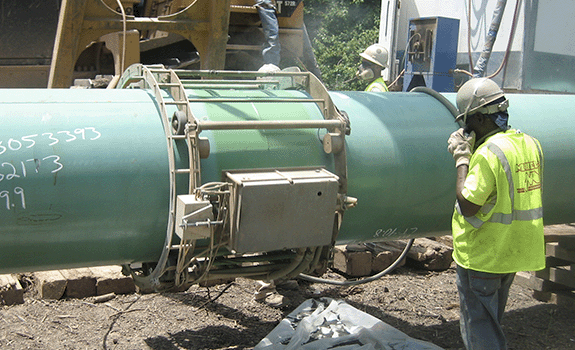

A signature of our commitment to unrivalled customer service, our comprehensive training is available to distributors and contractors alike and can be undertaken at our dedicated training centre in London, on-site, or even virtually, to suit customer needs. Our highly knowledgeable Denso™ regional managers cover the entirety of the UK and Ireland to provide customers with training in correct and complete application methods. Recent training sessions include site visits to branches of Wolseley UK and Jewson Civils Frazer, along with Viking Johnson and Morrison Utility Services to provide training on the Denso™ P1 and P2 Systems – our CESWI 7th Edition compliant protection for ferrous pipes, joints and fittings in the water industry.

To register your interest in our free product application training, contact your local representative for more information or fill in the contact form here.

Denso™ Southern Area Manager, Oliver Capps (third from right) demos the Denso P1 System™ for Wolseley UK staff visiting the Viking Johnson factory in Hertfordshire.

WCI@140 Photo Competition – And the winner is…

Back in October 2023, we launched the Winn & Coales 140th Anniversary Photo Competition as a way of drawing our 140th year to a triumphant close and inviting you to become a small part of that celebration.

Firstly, we would like to thank everyone who entered. We were thrilled at the response from our customers and online followers and want to thank you all for joining in our celebrations.

So, with the competition now closed, who are the lucky winners?! In descending order…

Third place – Vipan K. from Botswana!

Vipan shared a brilliant photo of Denso CPT Tape™ which had been applied on a water pipeline project in Botswana. The unique perspective displayed in the photograph showcases the extremely professional and tidy tape application as the pipe waits to be lowered into the trench.

Second place – Richard R. from South Africa!

Richard was one of our first entries into the competition and set a high standard for the many that followed with this Archco 403D™ application during a petrochemical plant’s shutdown in September in South Africa. This unique shot was taken inside the water storage tank that Richard and his team had blast-cleaned and coated in only 11 days!

And finally, our winner, in first place, is – TAMS Group from Australia!

The TAMS Group submitted this incredible photo of a SeaShield 2000FD™ System application during pile remediation works in Western Australia. Our judges were extremely impressed with this truly unique shot, which spotlights an often-unseen perspective of pile repair and maintenance taking place below the water line.

We’re sure you will agree that all three of our winners submitted excellent photos that are extremely worthy of their placements.

Once again, we would like to thank everyone for their participation and helping us to celebrate our 140th anniversary!

Our photo competition winners are revealed, in descending order...

In third place...

In second place...

And in first place, our winner...

World Pipelines Q&A with… Chris Winn

Winn & Coales International Ltd. Group Chairman, Chris Winn recently sat down for an exclusive Q&A session with Elizabeth Corner for the December 2023 edition of World Pipelines Magazine. In this article, Chris reflects on the company’s landmark achievement of 140 years’ service to industry and how the company has evolved in this period.

Let’s begin with the reason that this year is so important to Winn & Coales International Ltd. Founded in 1883, the company celebrates its 140th anniversary in 2023: tell me first, how have you been celebrating?

Planning for our 140th year began in early 2022 with the creation of a dedicated logo to mark the occasion, drawing inspiration from our 100th and 125th anniversary logos and leaning heavily into the long history of tradition which we are so proud of at Winn & Coales. This logo has been featured in all our 140th anniversary celebrations, from specially commissioned anniversary gifts to prominent positions in our exhibition displays this year. At the beginning of 2023 we also implemented a comprehensive communications campaign across both digital and print media to formally announce our anniversary.

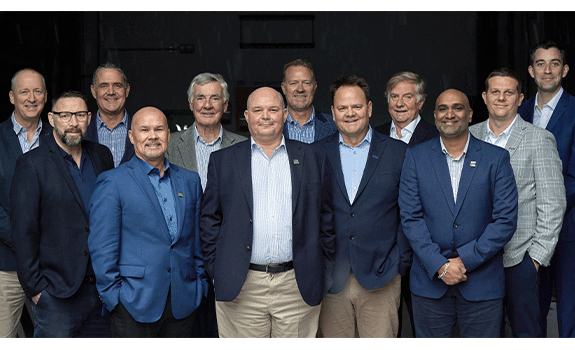

We recognise the part played by our dedicated colleagues in helping us reach our 140th year of trading. As a thank you for their hard work and dedication, we hosted a special edition of our Annual Dinner and Dance this year at the prestigious Mansion House in London, marking the end of a week-long conference held for the Managing Directors of our subsidiary companies from around the world.

In addition to our colleagues working directly within Winn & Coales, we work extremely closely with our extensive network of agents and distributors operating across the vast number of territories where our products are available. Our biennial Denso Asian Conference – last held in 2018 due to the onset of the COVID-19 pandemic – returned in August of this year, allowing us to extend our anniversary celebrations even further afield and affording everyone with the opportunity to reconnect and celebrate after so many years working remotely.

Through the work of Winn & Coales International Ltd. and the F.B. Coales No.4 (Family) Trust – founded by the late Frank Coales, our second company Chairman – we recognise the work of previous employees from the locale of West Norwood. On-going charitable donations allow us to give back what individuals have put into the business in the last 50 years that we have been operating from our Chapel Road headquarters.

Finally, we have launched the Winn & Coales 140th Anniversary Photo Competition to finish out 2023, as a thank you to our long-standing customers for their support over the many years we have been operating. It’s an exciting way for individuals to show us their best Denso™ product application shots to be in with the chance of winning a very special prize. It’s a fun way to bookend what has been a fantastic year of celebrations.

Can you talk us through the ways in which the company has grown and changed over the years? I want to understand the journey of your company from its inception to this significant milestone: what have been some of the key milestones and challenges along the way?

The international-scale operation you see before you today was first established as an import/export house in London. Originally specialising in the exportation of coke to Germany, the business later expanded into importing starches, sugars, soda crystals and waxes.

The first foray into manufacturing came in 1905, with continued growth in this area throughout the 1920s before we took on the agency for a petrolatum-based tape designed for the corrosion prevention of steel pipes, fittings and structures in 1929. The product was called Denso Tape, and following increasing sales in the intervening years, we started to manufacture it in London under licence from 1933. This would be a major turning point for us, and we have now been manufacturing petrolatum tapes for over 90 years.

From there, our continued success can be attributed to our focus on the corrosion prevention market, the development of our export markets, including establishing subsidiary companies and six factories around the world, and responding to the changing needs of our customers and meeting these requirements with expanded product offerings.

Running companies on different continents exposes us to unique regional challenges, yet we continuously manage for change. In recent times this has been demonstrated by the company showing amazing resilience during the pandemic, war in Ukraine and against global economic considerations. With our forward-thinking mindset, we continue to adapt and innovate for the future.

How has the energy industry evolved since the company was founded and how do you approach change at Winn & Coales? Tell me how the company is adapting to the new challenges in the energy space.

We have noticed considerable and far-reaching changes to the energy industry, particularly over the last fifty years. Pipelines are being installed at far greater depths than they were post-WW2 and running at ever higher operating temperatures. In terms of corrosion prevention, solutions need to work harder and be far more accommodating of the demands being placed upon pipelines.

Factory coatings have also seen substantial reforms in recent years with the adoption of a greater focus on the environmental concerns regarding pipeline construction and maintenance. The utilisation of horizontal directional drilling (HDD) applications is increasing in high consequence areas, meaning more pipelines are being exposed to ever more severe ground conditions.

At all of our sites we have research and development teams who are continuously researching and developing our products and systems to adapt to these new demands.

How has Winn & Coales embraced technological advancements and used these to the benefit of the sector?

One of our greatest strengths is utilising local and international knowledge acquired by our teams around the world to inform the wider group of companies through regular international conferences and meetings. We draw this experience from our subsidiary companies and use it to innovate and improve our products and systems.

We also continually assess customer feedback to continue to evolve and develop technologies to deal with new challenges – for example, transitioning from petrolatum to bitumen-based solutions, and most recently to meet the demands for visco-elastic products and subsequent new patented systems. Regularly communicating with our customers and using their feedback helps to inform our direction going forward and is firmly entrenched in our commitment to the BS EN ISO 9001:2015 Quality Management Systems standard.

Can you tell us about any notable achievements along the way? In what ways has Winn & Coales contributed to the pipeline industry?

Within the last 15 years, we have been recognised a total of three times for our exceptional export sales performance and were the recipients of three Queen’s Awards for Enterprise in International Trade (Winn & Coales International Ltd. in 2010 and 2013, and Premier Coatings Ltd. in 2017).

Winn & Coales International Ltd. subsidiaries have also forged long standing relationships with the major EPC and pipeline construction companies around the world offering them guaranteed quality, technical backup and service.

We have adopted a ‘technology neutral’ mindset at Winn & Coales. We believe that all coating systems offer different advantages and disadvantages, and that there is no coating method that surpasses all others. The acquisition of several competitors has bolstered the range of solutions we are able to supply to our customers. Our most notable recent acquisition was for the global Viscotaq™ business, including Amcorr Products and Services Inc. (‘Amcorr’). The addition of visco-elastic protective coatings to our product offering means we can continue to offer systems that employ all kinds of coating solutions from a single source. Helping customers make the right choices for their projects with our growing product range is at the forefront of what we are trying to achieve.

Other areas of the business benefiting from company acquisitions has been our subsea and splash zone coatings with the takeover of the Simpson Strongtie FX-70 range in 2021, and the acquirement of Barrier Industrial Marine Products LLC in 2017. These acquisitions further establish us as a leading supplier of corrosion prevention systems for a wide array of industries and application types.

Finally, we are keen supporters and contributors to a number of industry bodies on national and international levels, as members of ICORR (Institute of Corrosion), PIG (Pipeline Industries Guild) and AMPP. We are also Associate Members of IPLOCA with WCI Executive Director Andrew Stuart serving on the IPLOCA Board of Directors since 2021.

We know that sustainability and environmental responsibility are increasingly important in the energy industry. How does Winn & Coales prioritise and integrate these principles into its operations? How do you see this continuing into the future?

Greenhouse gas emissions caused by the energy industry are a significant contributor to overall global greenhouse emissions and corrosion exacerbates that issue. Efficient, long-lasting corrosion prevention systems mitigate this problem; by designing our products to last and protecting our customers’ assets for a considerable amount of time, we help to reduce the overall carbon footprint generated by the pipeline industry. We are therefore fully committed to reducing the environmental impacts generated by our production processes and our products, as evidenced by our BS EN ISO 14001:2015 Environmental Management System (EMS) accreditation.

We have operated an EMS on site for over 10 years now and have implemented multiple energy management programs to minimise our carbon footprint. As recently as this year, we have made the transition to using 100% renewable electricity at our Chapel Road premises, generating solar power from the installation of photovoltaic panels to our laboratory and office buildings. Enshrined within our EMS is a commitment to the continual improvement of our environmental performance which will see us continuously assessing and refining our business operations in order to contribute toward a greener future for our planet.

What is it about Winn & Coales that ensures the company is thriving 140 years later? As the Chairman, what do you consider to be the company’s greatest strengths and differentiators in the energy services market? How do you maintain a competitive edge?

Our vision is to be the leading manufacturer and supplier of anti-corrosion, waterproofing and sealing materials and technology to the world. This is our company mission which lies at the heart of all our business-making decisions. We have an intricate focus on and understanding of our core business functions, and it is this focus that has guided us for the past 90 years.

Running parallel to our vision is our commitment to providing unrivalled high-quality service to our customers. One of our greatest strengths is our people; employing highly knowledgeable experts on the ground interacting with our customers daily in both domestic and overseas markets is crucial to good business performance, and never more so than when we gather our intelligence to inform the innovation of new technologies for the benefit of our customers.

To this day we remain a privately owned and independent business, which enables us to be extremely nimble and able to react very quickly to meet changing market demands. The strength of the ‘Denso’ brand name itself and our long-held reputation for quality products has helped to establish our position within our field. As we move forward from our 140th year, we believe the continuity of strong leadership across the group of companies, alongside an ongoing multimillion pound programme of investment in the group around the world, will see the company grow and prosper for many more years to come.

How would you describe the essence of the company? Do you have a company motto, or ethos you’d like to share with us? I wonder if there is an employee who comes to mind who particularly embodies the values hold dear?

At Winn & Coales International Ltd., we are firm believers in the power of people, people, people. The intrinsic value of the individuals who support our business to operate successfully can never be understated. The hard work and dedication demonstrated by our teams across the globe are crucial to our success and achieving our operational goals.

There is a great sense of family amongst our employees, and with that comes a shared responsibility and duty to work together as a team. With family, there is a shared respect for each other and the legacy of the company within which we work. Together, we strive for excellence and work towards a common goal.

Across the group we have many people who have served 20, 30, or 40+ years in all divisions – from the shop floor to the board of directors. Our longest serving employee to date dedicated 62 years of loyal service in total.

When it comes to your customers: how do you create and foster long-term relationships? What are the challenges in this space for pipeline manufacturing and service companies?

Endeavouring to provide the highest levels of customer service is paramount to us. It is extremely important that our customers are confident in the correct application techniques for our products and systems; in this vein, we offer free product application training that can be undertaken at our dedicated training centres around the world or at our customer’s site. Training and engaging with our customers in this manner can nourish those all-important relationships that are critical to good business relations.

As previously mentioned, we are fortunate to possess real experts with decades of knowledge and experience behind them. The continuity offered by long serving staff members plays a huge role in fostering relationships. The difficulties we can face are down to turnover in our customers personnel and losing the connection nurtured over many years of business.

Additionally, rising energy costs and the fluctuating price and availability of raw materials are some of our most difficult challenges to navigate. Proficient resource planning and maintaining a consistent eye on world events and markets means we can successfully navigate these issues.

Last thoughts then: what is planned for the big 150th anniversary? What else will Winn & Coales have achieved by then?

Our main focus is to continue as leaders within the field of corrosion prevention and sealing technologies, pushing for growth in all of our markets and managing the acquisition of more companies to complement our existing range of products and systems. We are two years in to a very ambitious 10-year growth strategy where we aim to quadruple the size of the business, which we are currently on track to achieve.

In the meantime, we will continue to reflect on our past and take what we learn to propel ourselves toward a positive and bright future. As for the big 150th – you’ll have to wait and see!

The original article can be found on pages 21-25 of the December 2023 edition of World Pipelines magazine. Alternatively, you can view the issue online by clicking here.

World Pipelines Q&A with Chris Winn

WCI Group Chairman, Chris Winn

The renowned anti-corrosion petrolatum tape, Denso Tape, was first manufactured by WCI in 1933.

The range of products and systems offered by WCI continues to grow, most recently with the acquisition of Viscotaq Visco-elastic Coatings in 2021.

Sharing knowledge and training in the importance of correct application procedures at the Denso Asian Conference in August 2023.

Directors from across the WCI group of companies assembled in London for a group conference and celebratory dinner and dance in November 2023.

St. Luke’s Pond Revamp Funded by F.B. Coales No.4 (Family) Trust Donation

The F.B. Coales No.4 (Family) Trust continues in its mission to support good causes around Southeast London and Kent. Last year, the Trust were delighted to offer their support to St. Luke’s CofE Primary School in West Norwood – a mere two streets away from the Winn & Coales International Ltd. (WCI) head office!

St. Luke’s supports 188 children between the ages of 4 and 11 to become successful learners, confident individuals and responsible citizens. Exposure to a wide curriculum of subjects combined with access to a range of outdoor spaces and extra-curricular activities, encourages pupils to succeed and achieve their personal best in a warm, caring and inclusive environment.

The F.B. Coales No.4 (Family) Trust were approached by the PFA (Parents and Friends Association) at St. Luke’s in early 2023 to see how they could help to further enrich the learning opportunities provided for the students. After some positive discussions, the Trust were thrilled to donate £10,000 to help revamp the school’s outdoor pond area and for the Special Educational Needs Coordinator (SENCo) to purchase additional learning aids for the school.

A valuable learning resource, the pond and nature area bring the classroom outside, providing an exciting new environment for students to explore. Sophia Bryan-Whyte, the headteacher of St. Luke’s said, “The children can read about the wildlife, but coming in to see actual plants oxygenating the pond, it makes a difference for the learners.”

Over time, the pond had become overgrown and in need of refurbishment; with the Trust’s donation, St. Luke’s commissioned the expert help of Sprout Up – Schools to breathe new life into this educational outdoor space. Seonaid Royall from the company said, “Sprout Up – Schools was built to be able to help schools like St. Luke’s build their pond area, making a derelict space more beautiful and useful for the children.”

The ‘Water Life Area’ was officially opened in September 2023 after a busy summer of renovation works by Sprout Up – Schools and Thomas Patrick Landscapes, with pupils able to enjoy renewed learning opportunities in the great outdoors for the 2023/24 school year. Amari Bempah, a Year 5 learner at St. Luke’s, thanked WCI and the Trust at the grand opening, saying, “Thank you so much for making the pond better; we appreciate and love it very much.”

The Trust’s donation also helped the SENCo leader at St. Luke’s to purchase additional learning materials and items for students with special educational needs and disabilities (SEND). A range of wobble stools, wobble feet, ear defenders and chew toys were purchased to support pupils who benefit from additional help in the classroom to assist them in their day-to-day learning. The teachers have already seen these items make a positive impact on their students and will no doubt see further benefit to more pupils in the future.

Sarah Hashmi, F.B. Coales Trustee, said, “It was an honour to attend the grand opening of the new pond area and I would like to extend my thanks to everyone at the school for making me feel so welcome and for the lovely warm reception we received.

It was clear to see the children were so excited and engaged with the new pond area and I am sure it will be a valued learning resource for many years to come. The team at Sprout Up – Schools did an amazing job, and it was lovely to meet the team responsible for creating this haven of tranquillity in the middle of West Norwood.

The wobble chair was actually very comfortable too and it is good to hear how these additional resources are benefitting the students that use them.”

For further information about the work of the F.B. Coales No.4 (Family) Trust, read our blog post here.

The grand opening of the new 'Water Life Project'.

The pond area before.

The ribbon cutting.

The 'Water Life Project'.

Sarah Hashmi and pupils from St. Luke’s CofE Primary School.

Students explore the renovated pond.

Students discovering the pond life.

The dedication plaque.

World Pipelines Coatings Q&A 2024

USA Technical Director for Denso, Inc., Eric Stark, recently featured in a Coatings Q&A for the January 2024 edition of World Pipelines Magazine. In this article, Eric discusses the range of pipeline coatings available from Denso, Inc., plus application training and product innovation.

1. What type of coatings does your company provide and how do they meet the challenges faced by pipeline operators and owners? What are the primary performance characteristics of your coatings products?

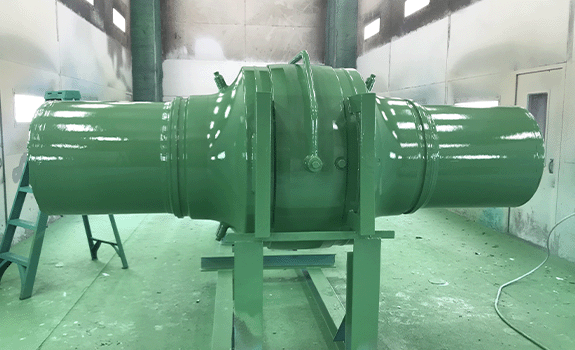

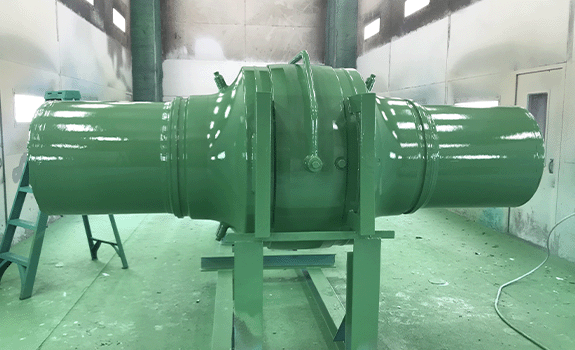

Denso, Inc. – a member of Winn & Coales International Ltd. – supplies protective coating solutions for a wide range of field-applied pipeline applications. To address the many application types utilised in the field, Denso supplies an extensive range of products using numerous materials such as liquid epoxy, vinyl ester, and urethane coatings, petrolatum tapes, viscoelastic coatings, fiberglass wraps, bitumen tapes, and butyl tapes. Primary among the liquid coatings are epoxy-based coatings used for coating weld seams, elbows and tees, etc. during construction, as well as replacement of damaged or defective coatings on existing pipelines. Protal 7200™ is the preferred liquid coating for this type of application due to its excellent balance of cathodic protection, fast return to service, ability to be applied using a variety of methods, adhesion, and abrasion resistance. Other Protal™ liquid coating options are also available to handle sweating pipe, directional drill pipe, high temperature pipe, and cold application conditions.

Our petrolatum, viscoelastic, fiberglass, bitumen and butyl tapes provide outstanding corrosion protection in combination with ease of application and minimal surface preparation. Once applied, they can provide corrosion protection over a wide temperature range. Our petrolatum tapes have a long history of over 90 years of successful service, and our Viscotaq™ viscoelastic coatings have the added benefit of exhibiting self-healing behaviour if a holiday develops. Fiberglass wraps are used to provide additional protection for external forces on the petrolatum and viscoelastic tapes. Denso manufacture a heavy-duty fiberglass wrap (Denso Bore-Wrap™) that has been specifically designed for use on the weld seams and full lengths of directional drill pipe as an abrasion/gouge resistant wrap. Finally, our bitumen and butyl tapes provide exceptional adhesion to pipe surfaces along with excellent corrosion protection.

2. How do you define correctly applied, fit-for-purpose pipeline coatings? Which standards do you hold up as the gold standard?

Correctly applied, fit-for-purpose pipeline coatings are defined by proper surface preparation; mix ratio and thorough mixing (if applicable); lack of defects (holidays); and cured or applied performance properties, such as cathodic disbondment, adhesion, and hardness. There are several standards which apply to field-applied pipeline coatings regarding correct application and fit-for-purpose characteristics – these include AMPP SP-0105, ISO 21809-3 and CSA Z245.30 for field-applied liquid coatings. In North America, the AMPP and CSA standards are both highly regarded, but since a large percentage of pipelines are owned by Canadian companies the CSA standard is probably the “gold standard”.

3. Can you talk about coatings in terms of innovation and advancements?

In terms of innovation and advancements, there continues to be effort placed on developing new coatings that can be applied at cold temperatures to broaden the window during which liquid coatings can be applied in the field. This is particularly important in Canada, the northern US, and other cold climate countries.

At all of our sites we have research and development teams who are continuously researching and developing our products and systems to meet these new demands.

4. How environmentally friendly can pipeline coatings be?

Pipeline coatings such as Protal 7200™ are typically 100% solids – meaning virtually no solvent, which limits the contribution to airborne pollutants. In addition, once cured, the level of extraction of harmful compounds is minimal due to the inert nature of the cured coating. There has been considerable effort by suppliers to the pipeline coatings industry to offer materials that are sustainable and even recyclable, but these normally come at a cost. The extent to which the pipeline industry accepts these new materials, and the associated costs, will determine how environmentally friendly pipeline coatings can be.

Tape products are typically more environmentally friendly than liquid coatings due to the lack of reactive chemicals but are not suitable for all applications.

5. What does application and training look like for your product?

It’s important to us that our customers feel confident in applying our systems and we take great pride in training teams to the highest standard in application methods. Denso provides free virtual training via Zoom and Teams using our dedicated in-house training facilities where we can physically demonstrate how to properly apply any of our pipeline products. We can also provide on-site training as needed.

As mentioned earlier, Protal 7200™ can be applied using a variety of methods. These include manual application using an applicator pad or paint brush and spray application using a plural airless spray apparatus, an automated spray ring, or a spray gun using cartridges. After successfully attending the training on these application methods, the applicators receive a certificate card to carry with them to prove they have been trained on how to properly apply our products.

6. Can your coatings be customised or tailored to specific project requirements?

Denso offer tailor-made solutions and are able to develop new products customised to specific project requirements when an existing product (or products) is not appropriate or approved for the application.

Typically, existing pipeline formulations are not changed in any way as they are normally qualified by owners and would require requalification if modified. However, Denso does have the capability to package our coatings per customer or project requirements, and can also customise the width and length of our tape products should this be required.

To read the article in full, head to pages 27-34 of the January edition of World Pipelines magazine. Alternatively, you can view the issue online by clicking here.

World Pipelines Coatings Q&A 2024

Application of Protal 7200 in the field.

Protal 7200 can be easily applied by brush...

...roller...

or spray.

Protal 7200 application.

WCI & Charitable Trust Support Local Foodbank to Fight Food Poverty

Winn & Coales International Ltd. (W.C.I.) and the F.B. Coales No.4 (Family) Trust were delighted to support the Norwood & Brixton Foodbank with a £25,000 donation in 2022. The donation has now funded the hire of an electric delivery vehicle and driver for a 12-month period, increasing food parcel deliveries across the borough.

The foodbank, part of the Trussell Trust’s UK foodbank network, is a lifeline for the local community, providing emergency food parcels, advice, and support in times of crisis. Operating since 2011, the foodbank serves all of Lambeth and north Croydon, with a team of dedicated volunteers working to provide much-needed items to families in need.

“The sheer scale of the foodbank’s operations is astounding, matched only by the professionalism and kindness of the volunteers working there,” said Sarah Hashmi, an F.B. Coales Trustee. “We’re overjoyed to support the foodbank’s great work to reach more families facing food poverty in Lambeth.”

W.C.I. is a leading manufacturer and supplier of corrosion prevention and sealing technologies based in West Norwood, London. The F.B. Coales No.4 (Family) Trust was set up by company co-founder Frank Coales, and today has three trustees and is a registered charity (no. 1179856).

W.C.I.’s Sarah Hashmi (far right) joins volunteers from Norwood & Brixton Foodbank at the unveiling of their new delivery van.

The foodbank operates from St. Margaret the Queen’s Church, Streatham.

Sarah Hashmi is provided with a tour of the facility by Elizabeth Maytom MBE, Project Lead at the Norwood and Brixton Foodbank.

The foodbank provides a vast number of items to people in need.

Donations are collected and processed by volunteers.

Food parcels collated ready for delivery.