CASE STUDY

Denso Bore-Wrap™ Protects Joints During Sliplining

Buried Coatings

Project Data

| Location | London, UK |

| Client | Thames Water |

| Distributor | Burdens Thurrock |

| Contractor | Barhale |

| Products | Denso Bore-Wrap™ and Denso Poly-Wrap |

| Date | 2024 |

Project Details

Denso Bore-Wrap™, a field-applied, sacrificial abrasion resistant outerwrap (ARO) from Winn & Coales (Denso) Ltd, was specified by the client, Thames Water, to protect welded pipe joints during sliplining on a recent project in the nation’s capital city.

After the pipe was welded and the aluminum foil tape applied to replace the barrier, it was essential that the joint be protected from abrasion and gouging during the sliplining process. Denso Bore-Wrap – an ARO designed specifically for trenchless installation, horizontal directional drilling (HDD) and boring operations – provided the ideal solution for the contractor, Barhale, who found the easy application and fast cure of the product allowed for the project to run smoothly and in-line with the existing welding timing.

The Bore-Wrap system provided reassurance to the client that the once vulnerable joint could be pushed through with no damage or compromise to the pipeline’s integrity.

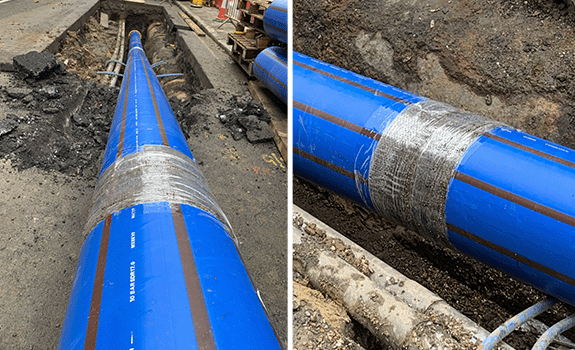

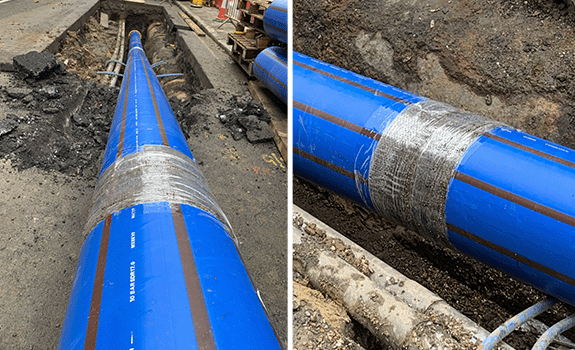

A completed Bore-Wrap application ready to be pulled through.

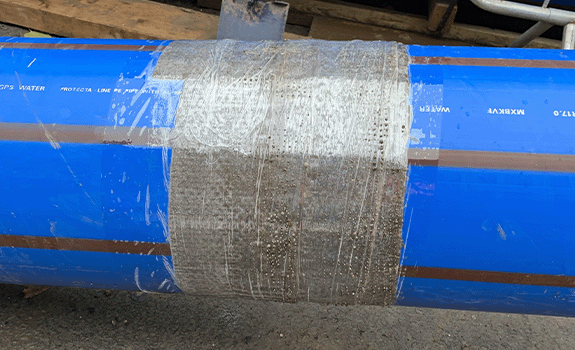

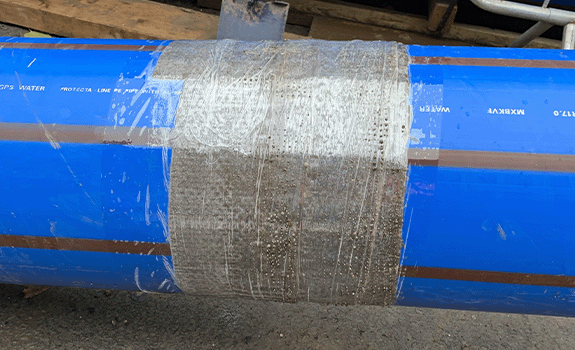

The pipe joint is protected with Denso Bore-Wrap prior to pulling, with the Denso Poly-Wrap applied over the top of the ARO (and perforated) in order to help the Bore-Wrap fully cure.

A completed Bore-Wrap application ready to be pulled through.

A completed Bore-Wrap application ready to be pulled through.

The pipe joint is protected with Denso Bore-Wrap prior to pulling, with the Denso Poly-Wrap applied over the top of the ARO (and perforated) in order to help the Bore-Wrap fully cure.