CASE STUDY

ONGC Tank Base Protection

Exposed Surface Coatings

Project Data

| Location | Mumbai, India |

| Client | ONGC |

| Products | Hi-Tack™ Primer, Hi-Tack™ Tape, Densyl™ Mastic, Denso Primer D™, Denso Ultraseal RT™ Tape, Denso Acrylic Topcoat™ |

| Agent | 3S Engineering |

| Contractor | LizMontagens India |

| Date | 8th May 2019 |

Project Details

ONGC is the largest crude oil and natural gas company in India, contributing to around 70% of Indian domestic production. Crude oil is the raw material used by downstream companies like IOC, BPCL, and HPCL to produce petroleum products like petrol, diesel, kerosene, naphtha, and cooking gas-LPG. This large natural gas company ranks 11th among global energy majors, 18th in ‘Oil and Gas operations’ and 183rd overall in Forbes Global 2000.

The ONGC plant at Uran, which is close to sea, has severe corrosion issues. It’s tanks, which are more than 30 years old, are severely effected at the base. Old traditional systems weren’t helping overcome these problems and finally ONGC decided to try the most globally trusted Denso Steelcoat™ Tank Base Protection System.

It’s global track record and ease of application worked in favour of the Denso Steelcoat Tank Base Protection System. The Denso team carried out a half day training session with the application team and the system was applied to the first 79m tank, which consists of Denso Hi-Tack™ Primer and Denso Primer D™, with Densyl™ Mastic for profiling and sealing voids.

The team take a photo break

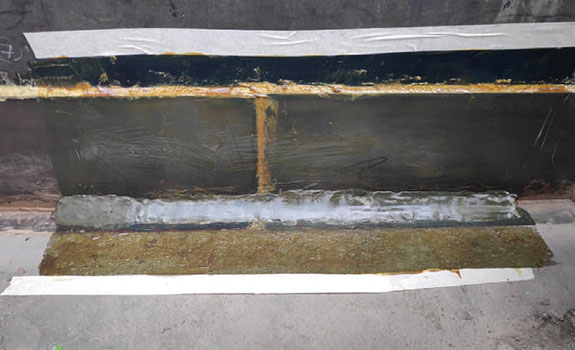

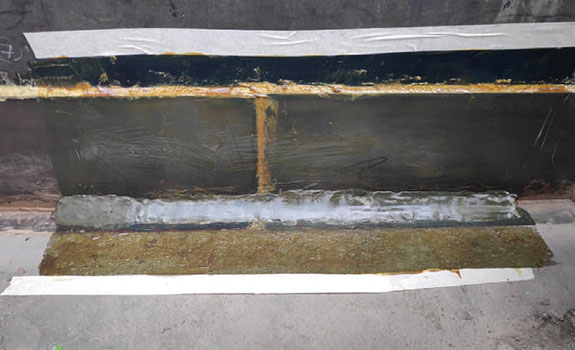

Application of Densyl™ Mastic and Denso Primer D™

Tank at the ONGC plant after the Denso Steelcoat™ Tank Base Protection System has been applied

Denso Hi-Tack™ Tape & Denso Ultraseal RT™ Tape applied

The team take a photo break

Application of Densyl™ Mastic and Denso Primer D™

Tank at the ONGC plant after the Denso Steelcoat™ Tank Base Protection System has been applied