CASE STUDY

Stornoway Deep Water Terminal Utilises SeaShield 2000FD™ System

SubSea & Splash Zone Coatings

Project Data

| Location | Isle of Lewis & Harris, Scotland |

| Client | Stornoway Port Authority |

| Contractor | Ocean Kinetics |

| Consultant | Wallace Stone |

| Products | SeaShield 2000FD™ System (Denso Paste S105™, Denso™ Marine Piling Tape and SeaShield 2000FD™ Jackets) |

| Date | 2024 |

Project Details

A £49 million project to create a Deep Water Terminal at Stornoway on the island of Lewis was carried out by McLaughlin & Harvey. The aim of the project was to create a multi-functional facility capable of berthing Cruise Ships and to accommodate large vessels servicing future renewable energy developments.

The facility has two berths with the main berth suitable for vessels up to 360 metres long and at low tides still has a water depth of 10 metres. On the Berthing Dolphin, Wallace Stone, Consulting Civil Engineers recommended the use of Winn and Coales (Denso) Ltd’s SeaShield 2000FD™ System to protect the piles in the splash zone.

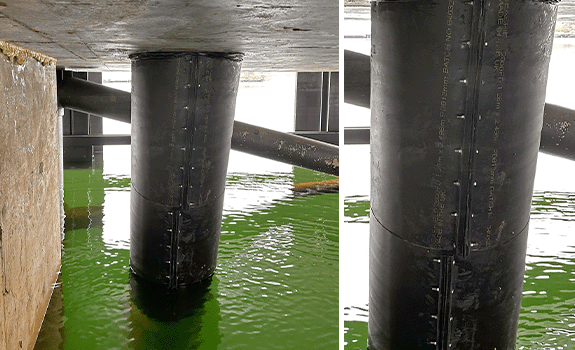

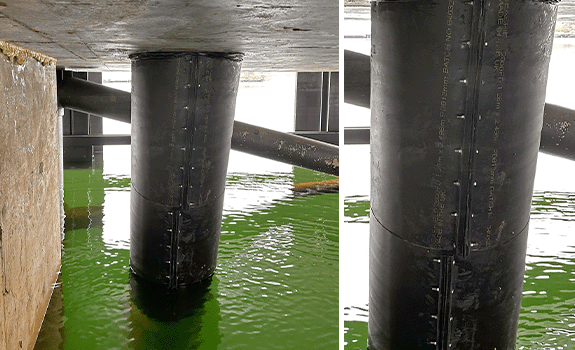

Consisting of Denso Paste S105™, Denso™ Marine Piling Tape and SeaShield 2000FD™ Jackets, the system provides proven long-term protection against corrosion. The HDPE jackets are installed using tensioning equipment and stainless steel bolts ensuring the jackets fit tightly around the pile.

The installation of the SeaShield 2000FD System was carried out by Ocean Kinetics with support from Winn and Coales (Denso) Ltd.

The HDPE jackets are installed with tensioning equipment and secured with stainless steel bolts.

A completed SeaShield 2000FD jacket installation.

The HDPE jackets are installed with tensioning equipment and secured with stainless steel bolts.