World Pipelines Coatings Q&A 2024

USA Technical Director for Denso, Inc., Eric Stark, recently featured in a Coatings Q&A for the January 2024 edition of World Pipelines Magazine. In this article, Eric discusses the range of pipeline coatings available from Denso, Inc., plus application training and product innovation.

1. What type of coatings does your company provide and how do they meet the challenges faced by pipeline operators and owners? What are the primary performance characteristics of your coatings products?

Denso, Inc. – a member of Winn & Coales International Ltd. – supplies protective coating solutions for a wide range of field-applied pipeline applications. To address the many application types utilised in the field, Denso supplies an extensive range of products using numerous materials such as liquid epoxy, vinyl ester, and urethane coatings, petrolatum tapes, viscoelastic coatings, fiberglass wraps, bitumen tapes, and butyl tapes. Primary among the liquid coatings are epoxy-based coatings used for coating weld seams, elbows and tees, etc. during construction, as well as replacement of damaged or defective coatings on existing pipelines. Protal 7200™ is the preferred liquid coating for this type of application due to its excellent balance of cathodic protection, fast return to service, ability to be applied using a variety of methods, adhesion, and abrasion resistance. Other Protal™ liquid coating options are also available to handle sweating pipe, directional drill pipe, high temperature pipe, and cold application conditions.

Our petrolatum, viscoelastic, fiberglass, bitumen and butyl tapes provide outstanding corrosion protection in combination with ease of application and minimal surface preparation. Once applied, they can provide corrosion protection over a wide temperature range. Our petrolatum tapes have a long history of over 90 years of successful service, and our Viscotaq™ viscoelastic coatings have the added benefit of exhibiting self-healing behaviour if a holiday develops. Fiberglass wraps are used to provide additional protection for external forces on the petrolatum and viscoelastic tapes. Denso manufacture a heavy-duty fiberglass wrap (Denso Bore-Wrap™) that has been specifically designed for use on the weld seams and full lengths of directional drill pipe as an abrasion/gouge resistant wrap. Finally, our bitumen and butyl tapes provide exceptional adhesion to pipe surfaces along with excellent corrosion protection.

2. How do you define correctly applied, fit-for-purpose pipeline coatings? Which standards do you hold up as the gold standard?

Correctly applied, fit-for-purpose pipeline coatings are defined by proper surface preparation; mix ratio and thorough mixing (if applicable); lack of defects (holidays); and cured or applied performance properties, such as cathodic disbondment, adhesion, and hardness. There are several standards which apply to field-applied pipeline coatings regarding correct application and fit-for-purpose characteristics – these include AMPP SP-0105, ISO 21809-3 and CSA Z245.30 for field-applied liquid coatings. In North America, the AMPP and CSA standards are both highly regarded, but since a large percentage of pipelines are owned by Canadian companies the CSA standard is probably the “gold standard”.

3. Can you talk about coatings in terms of innovation and advancements?

In terms of innovation and advancements, there continues to be effort placed on developing new coatings that can be applied at cold temperatures to broaden the window during which liquid coatings can be applied in the field. This is particularly important in Canada, the northern US, and other cold climate countries.

At all of our sites we have research and development teams who are continuously researching and developing our products and systems to meet these new demands.

4. How environmentally friendly can pipeline coatings be?

Pipeline coatings such as Protal 7200™ are typically 100% solids – meaning virtually no solvent, which limits the contribution to airborne pollutants. In addition, once cured, the level of extraction of harmful compounds is minimal due to the inert nature of the cured coating. There has been considerable effort by suppliers to the pipeline coatings industry to offer materials that are sustainable and even recyclable, but these normally come at a cost. The extent to which the pipeline industry accepts these new materials, and the associated costs, will determine how environmentally friendly pipeline coatings can be.

Tape products are typically more environmentally friendly than liquid coatings due to the lack of reactive chemicals but are not suitable for all applications.

5. What does application and training look like for your product?

It’s important to us that our customers feel confident in applying our systems and we take great pride in training teams to the highest standard in application methods. Denso provides free virtual training via Zoom and Teams using our dedicated in-house training facilities where we can physically demonstrate how to properly apply any of our pipeline products. We can also provide on-site training as needed.

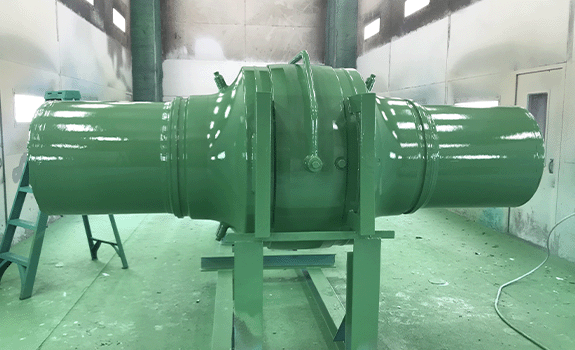

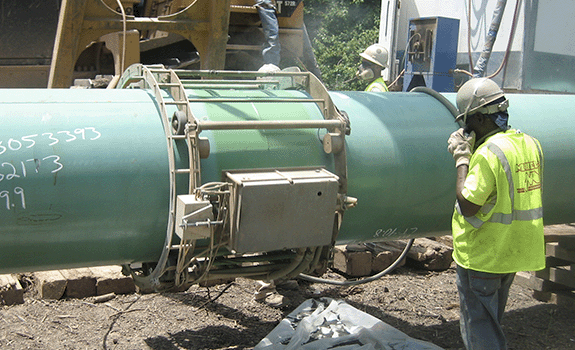

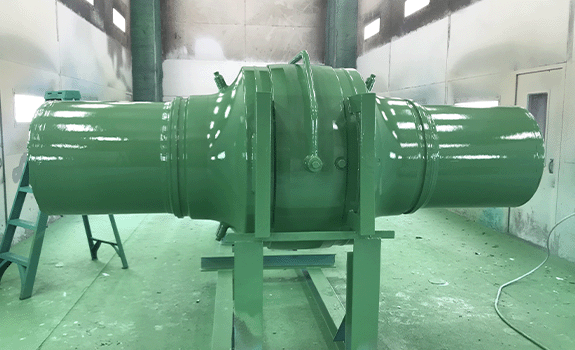

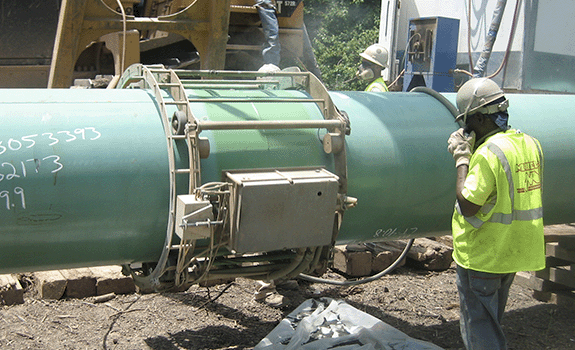

As mentioned earlier, Protal 7200™ can be applied using a variety of methods. These include manual application using an applicator pad or paint brush and spray application using a plural airless spray apparatus, an automated spray ring, or a spray gun using cartridges. After successfully attending the training on these application methods, the applicators receive a certificate card to carry with them to prove they have been trained on how to properly apply our products.

6. Can your coatings be customised or tailored to specific project requirements?

Denso offer tailor-made solutions and are able to develop new products customised to specific project requirements when an existing product (or products) is not appropriate or approved for the application.

Typically, existing pipeline formulations are not changed in any way as they are normally qualified by owners and would require requalification if modified. However, Denso does have the capability to package our coatings per customer or project requirements, and can also customise the width and length of our tape products should this be required.

To read the article in full, head to pages 27-34 of the January edition of World Pipelines magazine. Alternatively, you can view the issue online by clicking here.

World Pipelines Coatings Q&A 2024

Application of Protal 7200 in the field.

Protal 7200 can be easily applied by brush...

...roller...

or spray.

Protal 7200 application.

World Pipelines Coatings Q&A 2024

Application of Protal 7200 in the field.

Protal 7200 can be easily applied by brush...

...roller...

or spray.